Harnessing the Power of Computer Machining: Transforming Art Supplies, Product Design, and 3D Printing at Arti90

In today’s rapidly evolving technological landscape, computer machining stands out as a pivotal force driving innovation across multiple sectors. At Arti90, a leader in art supplies, product design, and 3D printing, integrating computer machining into workflows has unlocked unprecedented possibilities for artists, designers, and manufacturers alike. This comprehensive guide explores the multifaceted impact of computer machining on these industries, emphasizing how it enhances precision, efficiency, and creative potential.

Understanding Computer Machining: The Foundation of Modern Manufacturing

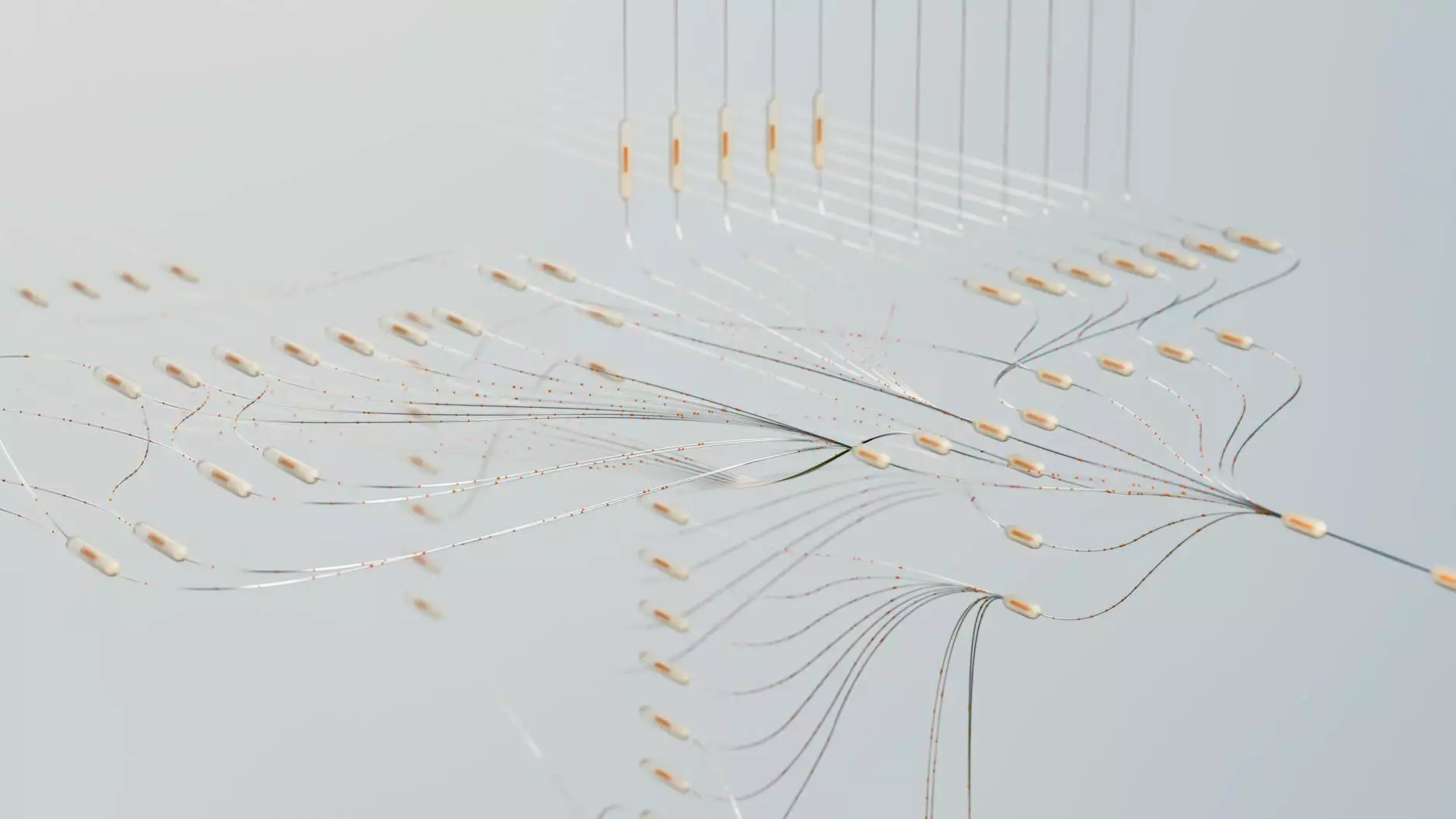

Computer machining, also known as CNC (Computer Numerical Control) machining, refers to automated control of machine tools through computer programming. This process allows for high-precision manufacturing of complex geometries that are difficult or impossible to craft manually. By utilizing sophisticated software, engineers and artists can design intricate patterns and prototypes, then have machines execute the manufacturing with unparalleled accuracy.

The core advantage of computer machining lies in its ability to translate digital designs into tangible products seamlessly. Whether creating detailed art supplies components, innovative product prototypes, or customized 3D printed parts, computer machining ensures consistency, repeatability, and quality at every stage.

Revolutionizing Art Supplies Manufacturing with Computer Machining

The realm of art supplies has traditionally relied on manual craftsmanship, often limiting detail, scale, and reproducibility. However, with the integration of computer machining, manufacturers like Arti90 are transforming the landscape by producing high-precision tools, brushes, easels, and accessories that elevate artistic performance.

Enhanced Precision and Consistency

Computer machining makes it possible to manufacture art supplies with exact specifications. For example, brushes with perfectly aligned bristles, rulers with finely calibrated markings, or paint palettes with uniform compartments become reliably reproducible. Artists gain confidence in the tools' quality, which directly influences their creative process.

Customization and Innovation

Custom art supplies—such as bespoke palette shapes, ergonomic handles, or niche artist tools—are now easier to design and produce through computer machining. This flexibility empowers artists and manufacturers to experiment with novel designs that meet specific artistic needs, fostering innovation and differentiation in the competitive art supplies market.

Material Versatility

With advances in computer machining, diverse materials like plastics, aluminum, and even ceramics can be precisely machined to create durable, lightweight, and aesthetically appealing art products. This material versatility broadens the scope for creative expression and product development.

Transforming Product Design: From Ideation to Production with Computer Machining

In the field of product design, speed, precision, and flexibility are crucial. Computer machining plays a vital role in streamlining the journey from conceptual sketches to fully realized prototypes and final products. At Arti90, this technology accelerates innovation cycles and elevates design quality.

Rapid Prototyping and Iteration

Designers can quickly transform digital models into physical prototypes using computer machining. This rapid turnaround enables multiple iterations, facilitating the refinement of form, fit, and function. The feedback loop becomes shorter, leading to better-designed products that meet market and user needs more effectively.

Complex Geometries and Custom Features

Modern computer machining supports complex shapes and intricate details that are challenging with traditional manufacturing. Whether it's ergonomic handles, geometric patterns, or embedded components, this technology empowers designers to push creative boundaries.

Cost-Effective Small Batch Production

For startups and small businesses, computer machining offers a cost-effective way to produce small batches with high precision. This reduces initial investment risks and allows for flexible production scheduling, promoting innovation and agility.

Advancing 3D Printing with Computer Machining: A Synergistic Approach

The relationship between computer machining and 3D printing is symbiotic, as both leverage digital designs for manufacturing. At Arti90, integrating these technologies creates a comprehensive ecosystem that enhances product capabilities and production efficiency.

Precision in 3D Printing Support Structures

Computer machining can produce components that serve as supports or fixtures for complex 3D printed parts, improving accuracy and surface finish. Additionally, machining can create molds or templates that streamline the 3D printing process.

Manufacturing of Custom 3D Printer Parts and Accessories

High-quality computer machining allows for the production of bespoke 3D printer components, such as extruder nozzles, heated beds, or filament guides, ensuring optimal performance and durability.

Hybrid Manufacturing for Unique Art Pieces

Combining computer machining with 3D printing opens new creative avenues for artists and designers. For example, intricate engraved details can be machined into a base, then complemented with 3D printed elements, resulting in multi-material, multi-texture masterpieces.

Elevating Quality and Efficiency at Arti90 with Computer Machining

As a leading innovator in art supplies, product design, and 3D printing, Arti90 leverages computer machining to deliver superior products that meet the highest standards of quality and precision. This technology reduces material waste, minimizes production errors, and enables complex geometries that push the limits of creativity.

The integration of advanced computer machining systems ensures that each batch of products is consistent, reliable, and ready to inspire. It also shortens lead times, accelerates market entry, and provides a competitive edge in a fast-paced industry.

Future Trends: The Next Generation of Computer Machining in Creative Industries

The future of computer machining in art, design, and manufacturing will be characterized by continued technological advancements, including AI-optimized toolpaths, automation, and the increasing use of sustainable materials. These developments will further empower creators to realize their visions with greater ease, speed, and eco-conscious practices.

Additionally, the rise of hybrid manufacturing strategies—combining computer machining with additive processes—will unlock new avenues for bespoke, high-performance products that seamlessly blend functionality with aesthetic appeal.

Why Choose Arti90 for Your Computer Machining Needs?

- Cutting-edge technology: State-of-the-art CNC machines and software ensure precision and reliability.

- Experienced team: Skilled professionals dedicated to quality control and innovative solutions.

- Broad material compatibility: From plastics to metals, accommodating diverse project requirements.

- Custom solutions: Tailored manufacturing processes designed to meet unique client specifications.

- Environmental responsibility: Sustainable machining practices minimizing waste and energy consumption.

Conclusion: Embracing Computer Machining for a Creative Future

The integration of computer machining in art supplies, product design, and 3D printing is not just a technological enhancement but a fundamental shift toward more creative freedom, higher quality, and sustainable manufacturing. At Arti90, this technology forms the backbone of our commitment to innovation, excellence, and empowering creators worldwide.

Whether you are an artist seeking precision tools, a designer crafting the next revolutionary product, or a manufacturer pushing the boundaries of 3D printing, embracing computer machining will set you on the path toward future-ready production and limitless creative possibilities.