Understanding the Importance of Grain Testing Equipment

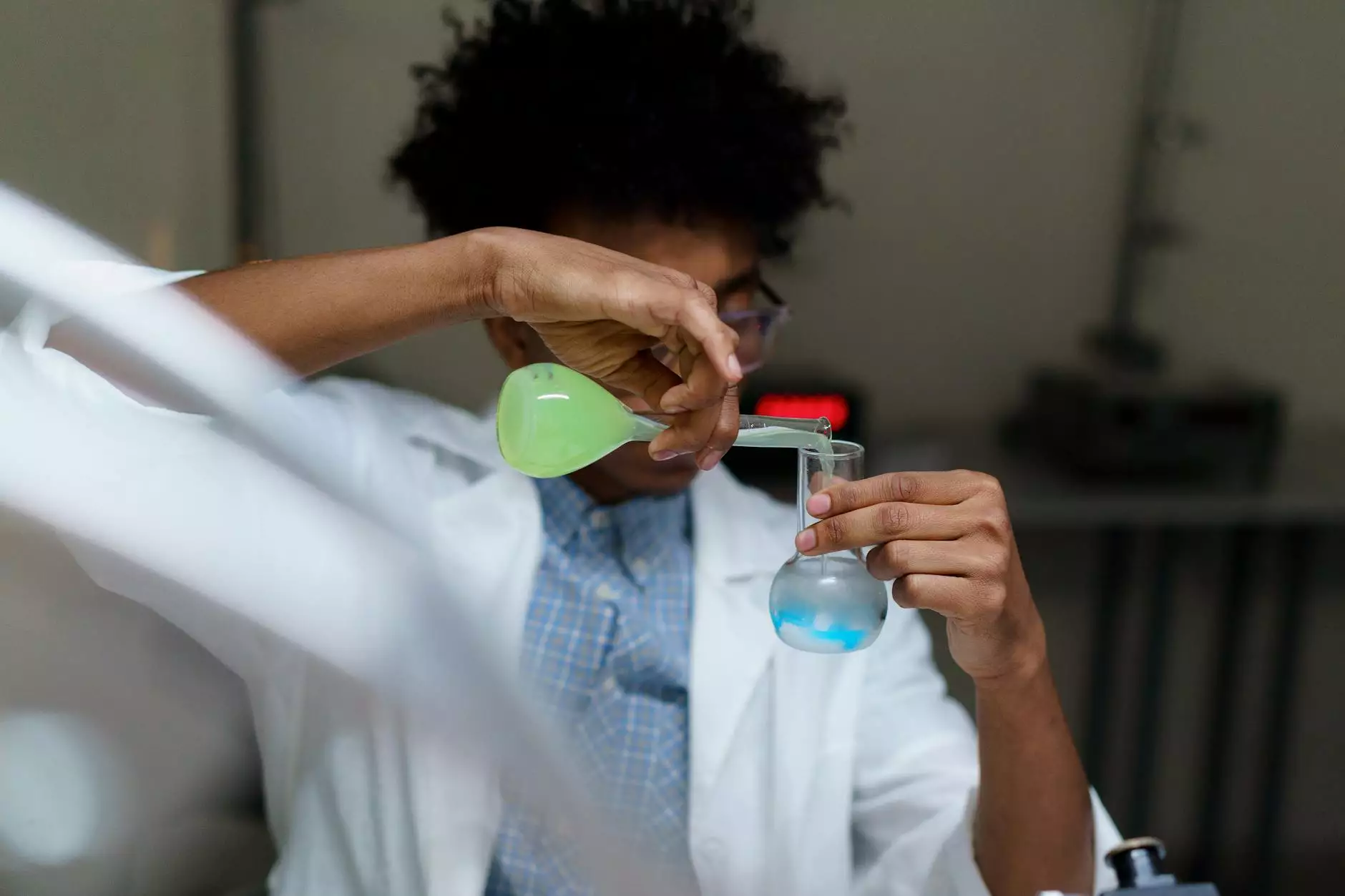

In the realm of agriculture, where the quality of produce directly impacts both yield and profit margins, grain testing equipment plays a pivotal role. This equipment allows farmers to evaluate the quality and safety of their crops, ensuring they meet industry standards and consumer expectations. By leveraging advanced grain testing techniques, farmers can maximize their operational efficiency and enhance the value of their harvest.

What is Grain Testing Equipment?

Grain testing equipment comprises various tools and instruments that enable the assessment of different properties of grains. These properties can include moisture content, protein levels, impurities, and overall quality. The precise testing of these parameters is crucial for farmers, grain handlers, and processors, as it affects storage decisions, marketing strategies, and end-use quality.

Types of Grain Testing Equipment

There are several types of grain testing equipment available on the market, each designed for specific testing requirements. Here are some common categories:

- Moisture Meters: These devices measure the moisture content in grains, essential for storage decisions to prevent spoilage.

- Protein Analyzers: Used to determine the protein level in grains, which impacts the nutritional quality and pricing.

- Impurity Separators: These machines help identify and eliminate foreign materials from the grain samples.

- Test Weight Scales: These scales measure the weight of grains, which correlates with quality and market value.

- Grain Sampling Tools: Essential for collecting samples that accurately represent the bulk of the grain.

Why is Grain Testing Equipment Essential?

The significance of grain testing equipment cannot be overstated. Here are several reasons why investing in high-quality grain testing equipment is beneficial for farmers and agricultural professionals:

1. Ensures Quality Control

Quality control is paramount in agriculture. With reliable grain testing equipment, farmers can:

- Detect problems early, such as high moisture levels that may lead to spoilage.

- Ensure that grains meet industry regulations and standards.

- Enhance product purity by removing foreign materials before selling.

2. Maximizes Profitability

By accurately assessing the quality of grains, farmers can:

- Negotiate better prices based on informed quality assessments.

- Minimize losses by choosing optimal storage methods based on moisture and impurity levels.

- Improve marketability by providing customers with high-quality grains.

3. Supports Sustainable Practices

Effective grain testing contributes to sustainability in farming by:

- Reducing waste through improved storage techniques.

- Encouraging the use of eco-friendly practices by identifying harmful contaminants.

The Evolution of Grain Testing Technology

The field of grain testing technology has evolved significantly over the years, integrating more sophisticated machinery and software solutions. Modern grain testing equipment uses advanced technologies such as:

- Near-Infrared Spectroscopy (NIR): A non-destructive method for determining moisture, protein, and oil content.

- Digital Imaging: For rapid assessment of grain quality and color grading.

- Automated Testing Systems: That provide consistent and accurate results while minimizing human error.

Choosing the Right Grain Testing Equipment

When selecting grain testing equipment, consider the following factors to ensure you invest wisely and effectively:

1. Testing Requirements

Identify what specific tests you need to conduct based on your grains. Different types of grains may require different testing standards.

2. Accuracy and Calibration

Ensure that the equipment you choose is known for its accuracy and can be easily calibrated. Regular calibration ensures that your results remain reliable.

3. Usability and Training

The equipment should be user-friendly, and consider vendor training to help your staff utilize it efficiently.

4. Customer Support and Warranty

Opt for suppliers that offer strong customer support and a robust warranty. This helps to mitigate downtime in the event of equipment malfunction.

Investment Considerations for Grain Testing Equipment

Investing in grain testing equipment can be a significant financial commitment. Here are some factors to weigh:

1. Cost vs. Benefit Analysis

Assess not just the upfront cost but also the long-term savings from improved efficiency and product quality.

2. Innovation and Updates

Consider how often the technology is updated and whether your current equipment can be upgraded to keep pace with advances.

3. Leasing vs. Buying

If budget constraints are an issue, explore leasing options, which can provide the latest technology without large upfront costs.

Conclusion

In summary, grain testing equipment is indispensable for modern farmers and agricultural professionals committed to excellence and sustainability. By investing in high-quality testing solutions, they can ensure better quality control, maximize profitability, and support sustainable farming practices. As the industry continues to evolve, staying abreast of technological advancements in grain testing will be crucial for farmers looking to maintain a competitive edge.

For more information about grain testing equipment and how it can benefit your farming operations, visit tsgcinc.com.